Ultimate Guide: How to Repair Any Home Window Frame (Wood, Vinyl, Aluminum & More!) 2025

Table of Contents

- Understanding Your Window Frames & Identifying Damage

- Essential Tools & Materials for Window Frame Repair

- Step-by-Step DIY Repair Guides

- Advanced Techniques & Common Associated Repairs

- Cost Analysis: DIY vs Professional vs Replacement

- When to Call a Professional

- Preventative Maintenance

- Frequently Asked Questions

Introduction

Are you tired of feeling cold drafts seeping through your windows? Frustrated by skyrocketing energy bills caused by inefficient window frames? Or perhaps you’ve noticed unsightly damage, rot, or deterioration around your window frames that’s affecting your home’s curb appeal and value?

You’re not alone. Window frame problems are among the most common home maintenance issues, affecting millions of homeowners annually. The good news? Many window frame repairs are completely within the realm of DIY capability, and knowing how to repair home windows frame properly can save you hundreds or even thousands of dollars.

This comprehensive guide will walk you through everything you need to know about diagnosing window frame damage, selecting the right repair approach for your specific frame material, and executing professional-quality repairs that will restore your windows’ functionality and appearance. Whether you’re dealing with rotted window frame repair on wooden frames or need to repair rotten wood window frame sections, we’ve got you covered.

What You’ll Learn in This Guide:

- How to accurately diagnose different types of window frame damage

- Material-specific repair techniques for wood, vinyl, aluminum, and fiberglass frames

- Essential tools and materials for each repair type

- Step-by-step repair procedures with professional tips

- Cost comparisons between DIY, professional repair, and full replacement

- Preventative maintenance strategies to avoid future problems

Let’s dive in and transform those problematic window frames into efficient, attractive features of your home!

Chapter 1: Understanding Your Window Frames & Identifying Damage

Common Window Frame Materials and Their Characteristics

Before learning how to repair home windows frame, it’s crucial to understand what type of frame material you’re working with. Each material has unique properties, advantages, and specific repair requirements.

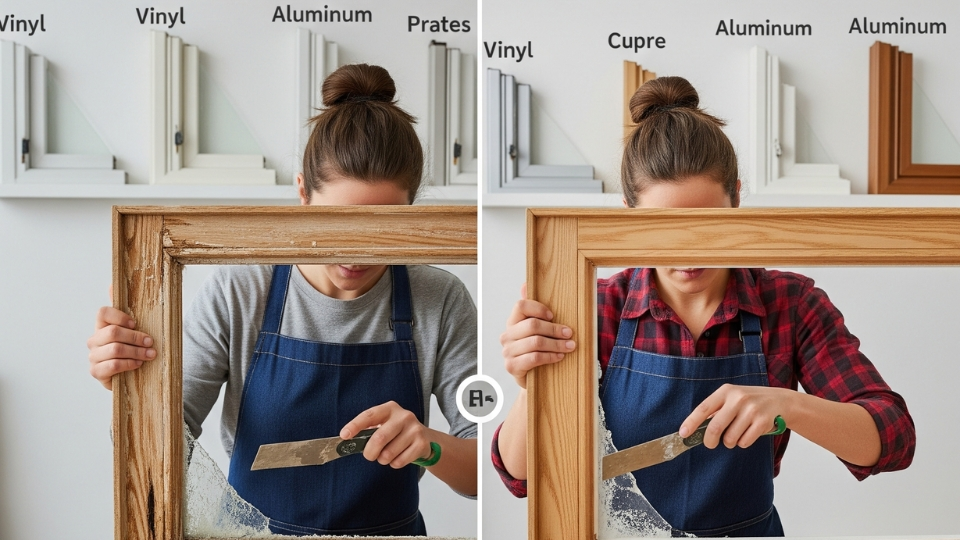

Wood Window Frames

Pros: Classic appearance, excellent insulation, paintable, repairable Cons: Susceptible to rot, requires regular maintenance, insect damage potential

Vinyl Window Frames

Pros: Low maintenance, good insulation, affordable, weather-resistant Cons: Can crack in extreme temperatures, limited color options, not paintable

Aluminum Window Frames

Pros: Lightweight, strong, long-lasting, corrosion-resistant Cons: Poor insulation, can dent, thermal conductivity issues

Fiberglass Window Frames

Pros: Excellent insulation, paintable, low maintenance, dimensionally stable Cons: More expensive, limited availability, specialized repair techniques

Types of Damage & Their Causes

Understanding the specific type of damage you’re dealing with is essential for effective rotted window frame repair or other restoration work.

Wood Frame Damage Types

Fungal Rot:

- Dry Rot: Brown, crumbly wood that breaks apart easily

- Wet Rot: Soft, spongy wood that’s often darker in color

- Causes: Moisture infiltration, poor ventilation, inadequate sealing

Insect Damage:

- Termite Damage: Hollow-sounding wood, mud tubes, small holes

- Carpenter Ant Damage: Large holes, wood shavings, rustling sounds

- Carpenter Bee Damage: Perfectly round holes, yellow staining

Other Wood Issues:

- Cracks from temperature fluctuations

- Warping due to moisture changes

- Paint failure exposing wood to elements

Vinyl Frame Damage Types

Physical Damage:

- Cracks from impact or temperature stress

- Punctures from sharp objects

- Warping from extreme heat exposure

Cosmetic Issues:

- UV discoloration and fading

- Chalking (powdery surface residue)

- Staining from environmental factors

Aluminum Frame Damage Types

Corrosion Issues:

- White powdery oxidation

- Pitting and surface deterioration

- Galvanic corrosion at connection points

Physical Damage:

- Dents from impact

- Scratches exposing bare metal

- Bent sections affecting operation

Fiberglass Frame Damage Types

Structural Issues:

- Hairline cracks in the surface

- Delamination of fiberglass layers

- Impact damage creating chips

How to Thoroughly Inspect Your Window Frames

Follow this systematic inspection checklist to identify all potential issues:

Visual Inspection Steps:

- Exterior Inspection:

- Look for obvious signs of rot, cracks, or damage

- Check paint condition and peeling areas

- Examine caulking and weatherstripping

- Note any gaps or separations

- Interior Inspection:

- Check for water stains or discoloration

- Look for condensation patterns

- Test frame stability by gentle pressure

- Examine window operation and alignment

- Detailed Examination:

- Use a flashlight to inspect corners and joints

- Probe suspected soft spots with a small screwdriver

- Check hardware mounting points

- Assess overall frame square and level

Tools for Inspection:

- Flashlight or headlamp

- Small screwdriver or awl for probing

- Moisture meter (for suspected water damage)

- Level and square for alignment check

Critical Signs: Repair vs. Replacement Decision Matrix

| Damage Type | Repairable | Consider Replacement |

|---|---|---|

| Wood Rot | Less than 25% of frame affected | More than 25% rot, multiple affected areas |

| Vinyl Cracks | Small cracks, limited number | Extensive cracking, structural cracks |

| Aluminum Corrosion | Surface oxidation, minor pitting | Severe corrosion, structural weakness |

| Frame Warping | Minor bowing, still operational | Severe warping affecting operation |

| Multiple Issues | Single material, localized problems | Multiple materials, widespread damage |

Red Flags Requiring Replacement:

- Structural integrity compromised

- Frame no longer holds glass securely

- Multiple repair attempts have failed

- Cost of repair exceeds 50% of replacement cost

- Historic or architectural significance requires professional restoration

Chapter 2: Essential Tools & Materials for Window Frame Repair

General Toolkit for All Window Frame Repairs

Having the right tools is crucial for successful repair rotten wood window frame projects and other window restoration work.

Safety Equipment (Non-Negotiable)

- Safety glasses or goggles: Protect from debris and chemicals

- Work gloves: Cut-resistant for handling sharp materials

- Dust mask/respirator: Essential when dealing with old paint or rot

- Knee pads: For comfort during extended work periods

Basic Hand Tools

- Utility knife: Sharp blade for cutting and scraping

- Putty scrapers: Various sizes for paint and material removal

- Wood chisels: Set of 1/4″, 1/2″, and 3/4″ for precision work

- Measuring tape: 25-foot minimum for accurate measurements

- Level: 2-foot and 4-foot levels for alignment checks

- Square: Combination square for 90-degree angles

Power Tools

- Oscillating multi-tool: Versatile cutting and sanding

- Cordless drill: Variable speed with clutch settings

- Random orbital sander: 5″ pad for smooth finishing

- Circular saw or miter saw: For cutting replacement materials

- Heat gun: For paint removal and material shaping

Fastening and Clamping

- Caulk gun: Heavy-duty for consistent application

- Clamps: Various sizes including bar clamps and C-clamps

- Screws and nails: Stainless steel to prevent corrosion

- Adhesives: Construction adhesive and specialized bonding agents

Material-Specific Supplies

Wood Frame Repair Supplies

For Rot Treatment:

- Wood hardener/consolidant: Penetrates and strengthens weak wood

- Two-part epoxy wood filler: Structural repair for significant damage

- Wood filler: Cosmetic filling for small holes and cracks

- Boric acid treatment: Natural fungicide and insecticide

For Replacement Sections:

- Matching wood species: Pine, fir, cedar, or hardwood as needed

- Wood preservative: Copper-based treatments for longevity

- Primer: High-quality bonding primer for bare wood

- Paint or stain: Exterior-grade finish matching existing

Professional Tip: Always use kiln-dried lumber for replacement sections to minimize future movement and cracking.

Vinyl Frame Repair Supplies

Crack and Hole Repair:

- Vinyl repair kits: Include color-matched compounds

- Plastic welding rods: For structural repairs

- Vinyl cleaner: Removes oxidation and prepares surface

- UV-resistant adhesive: Bonds without yellowing

Restoration Materials:

- Vinyl restorer: Rejuvenates faded surfaces

- Heat gun or hair dryer: For warming repair compounds

- Fine-grit sandpaper: 220-400 grit for surface prep

- Masking tape: Protects surrounding areas during repair

Aluminum Frame Repair Supplies

Corrosion Treatment:

- Aluminum oxide remover: Chemical treatment for oxidation

- Metal etching primer: Ensures paint adhesion

- Aluminum-compatible paint: Thermal expansion matching

- Corrosion inhibitor: Long-term protection coating

Structural Repairs:

- Aluminum epoxy: Structural bonding compound

- Metal filler: For dents and surface irregularities

- Fine steel wool: 0000 grade for surface preparation

- Aluminum foil tape: Temporary weatherproofing

Fiberglass Frame Repair Supplies

Crack and Chip Repair:

- Fiberglass repair kit: Includes resin, hardener, and cloth

- Gel coat: Color-matched surface finish

- Acetone: Surface preparation and cleanup

- Mixing cups and stirring sticks: Proper resin preparation

Downloadable Shopping Checklist

Basic Repair Kit ($75-150):

- [ ] Safety glasses and gloves

- [ ] Utility knife with extra blades

- [ ] Putty scraper set

- [ ] Caulk gun and exterior caulk

- [ ] Wood filler or vinyl repair kit

- [ ] Sandpaper assortment

- [ ] Primer and paint

Intermediate Repair Kit ($200-400):

- [ ] All basic kit items

- [ ] Oscillating multi-tool

- [ ] Heat gun

- [ ] Wood hardener and epoxy filler

- [ ] Clamps and construction adhesive

- [ ] Level and square

- [ ] Moisture meter

Professional-Grade Kit ($500-800):

- [ ] All intermediate kit items

- [ ] High-quality power tools

- [ ] Material-specific specialty products

- [ ] Advanced measuring tools

- [ ] Professional-grade finishes

- [ ] Comprehensive safety equipment

Chapter 3: Step-by-Step DIY Repair Guides

A. How to Repair Wood Window Frames

Wood frame repair is often the most complex but also the most rewarding type of window restoration. Here’s how to tackle common wood frame issues effectively.

Treating and Repairing Minor Rot

Skill Level: Intermediate | Time Required: 4-8 hours | Cost: $30-80

Safety Precautions:

- Wear respirator when disturbing rotted wood

- Ensure adequate ventilation when using chemical treatments

- Test for lead paint before sanding (homes built before 1978)

Tools and Materials Needed:

- Wood consolidant/hardener

- Two-part epoxy wood filler

- Chisels and scrapers

- Sandpaper (80, 120, 220 grit)

- Primer and paint

- Brushes and application tools

Step-by-Step Process:

- Assess the Damage

- Probe the affected area with a screwdriver

- Mark the extent of soft, rotted wood

- Determine if rot is surface-level or structural

- Remove Loose and Rotted Material

- Use a chisel to remove all soft, punky wood

- Scrape away loose paint and debris

- Clean the area with a stiff brush

- Allow to dry completely (24-48 hours)

- Apply Wood Consolidant

- Brush or inject consolidant into remaining soft wood

- Allow penetration time as per manufacturer’s instructions

- Multiple applications may be necessary for deep penetration

- Wait for complete curing (typically 24 hours)

- Fill with Epoxy Wood Filler

- Mix two-part epoxy according to instructions

- Apply with putty knife, slightly overfilling

- Work quickly as epoxy sets rapidly (10-20 minutes)

- Shape roughly to match original profile

- Sand and Shape

- Start with 80-grit sandpaper for rough shaping

- Progress to 120-grit for smoothing

- Finish with 220-grit for paint preparation

- Use sanding blocks to maintain flat surfaces

- Prime and Paint

- Apply high-quality bonding primer

- Allow proper drying time between coats

- Apply finish paint to match existing frame

- Consider using paint with mildewcide for added protection

Pro Tips:

- Work in temperatures between 50-80°F for best results

- Use a moisture meter to ensure wood is below 15% moisture before sealing

- Consider adding boric acid to consolidant for insect protection

Replacing Rotted Wood Sections

Skill Level: Advanced | Time Required: 6-12 hours | Cost: $50-150

When rot damage exceeds 25% of a frame section, replacement is often the better long-term solution.

Planning the Repair:

- Photograph the area before starting

- Measure carefully and create a template

- Source matching wood species and grain direction

- Plan cuts to minimize structural impact

Step-by-Step Process:

- Create a Template

- Use cardboard or plywood to create exact profile

- Account for any weathering or settling

- Test fit before cutting replacement piece

- Remove Damaged Section

- Make precise cuts with oscillating tool or saw

- Cut slightly inside the damage zone

- Preserve any salvageable adjacent material

- Clean cut surfaces thoroughly

- Prepare Replacement Piece

- Cut new piece 1/16″ oversized for final fitting

- Pre-treat with wood preservative

- Allow preservative to dry completely

- Test fit and adjust as necessary

- Install New Section

- Apply construction adhesive to joint surfaces

- Secure with corrosion-resistant screws or nails

- Clamp if possible for better bond

- Remove excess adhesive immediately

- Blend and Finish

- Sand joints smooth with surrounding material

- Apply wood filler to any small gaps

- Prime and paint to match existing finish

- Install new weatherstripping if needed

Fixing Cracks and Splits in Wood

For Small Cracks (less than 1/8″):

- Force wood glue into crack using syringe

- Clamp or tape to close crack

- Allow 24-hour cure time

- Sand smooth and refinish

For Larger Splits:

- Clean out debris from split

- Apply construction adhesive

- Insert wooden shim if gap is significant

- Clamp until adhesive cures

- Plane or sand flush when dry

B. How to Repair Vinyl Window Frames

Vinyl repairs require different techniques but can be very effective when done properly.

Repairing Small Cracks and Holes

Skill Level: Beginner to Intermediate | Time Required: 2-4 hours | Cost: $15-40

Materials Needed:

- Vinyl repair kit (color-matched)

- Heat gun or hair dryer

- Plastic spreaders

- Fine sandpaper

- Cleaning solvent

Step-by-Step Process:

- Clean the Damage Area

- Remove all dirt, grease, and oxidation

- Use vinyl cleaner or mild detergent

- Rinse thoroughly and allow to dry

- Sand lightly with 400-grit paper for adhesion

- Prepare the Repair Compound

- Warm vinyl compound to room temperature

- Mix components if using two-part system

- Work in small batches to prevent waste

- Apply the Repair

- Slightly overfill the crack or hole

- Use smooth, even strokes with spreader

- Feather edges to blend with surrounding area

- Remove excess material immediately

- Heat and Smooth

- Apply gentle heat with hair dryer

- This helps compound flow and self-level

- Avoid overheating which can cause discoloration

- Work quickly while compound remains pliable

- Final Finishing

- Allow to cure completely (usually 24 hours)

- Sand lightly with 400-grit paper if needed

- Apply vinyl protectant for UV protection

- Buff to desired sheen level

Different Vinyl Repair Kit Types:

| Kit Type | Best For | Pros | Cons |

|---|---|---|---|

| Liquid Patch | Small cracks, scratches | Easy application, flows well | Limited to surface repairs |

| Paste Filler | Holes, deeper damage | Builds thickness, sandable | Requires more skill |

| Heat-Weld Rods | Structural cracks | Strongest bond | Needs special tool |

C. How to Repair Aluminum Window Frames

Aluminum repairs focus primarily on corrosion treatment and surface restoration.

Fixing Minor Dents and Scratches

Skill Level: Beginner | Time Required: 2-3 hours | Cost: $20-50

For Small Dents:

- Clean area thoroughly with degreaser

- Use rubber mallet and backing block to work out dent

- Sand with 220-grit paper to smooth surface

- Apply metal primer and matching paint

For Scratches:

- Sand scratch with 400-grit paper

- Apply aluminum primer to bare metal

- Build up with thin coats of paint

- Wet sand final coat with 800-grit paper

- Polish to match surrounding finish

Treating Corrosion

Severe Oxidation Treatment:

- Remove Oxidation

- Use aluminum oxide remover (phosphoric acid-based)

- Follow manufacturer’s safety instructions

- Apply with brush, allow contact time

- Rinse thoroughly with clean water

- Surface Preparation

- Sand with 320-grit aluminum oxide paper

- Remove all loose material and white powder

- Clean with degreaser or alcohol

- Dry completely before proceeding

- Apply Protective Coating

- Use etching primer for maximum adhesion

- Apply thin, even coats

- Allow proper flash time between coats

- Finish with corrosion-resistant paint

D. How to Repair Fiberglass Window Frames

Fiberglass repairs use techniques similar to automotive bodywork.

Addressing Cracks and Chips

Skill Level: Intermediate | Time Required: 4-6 hours | Cost: $40-80

Small Crack Repair:

- Prepare the Crack

- Clean with acetone or degreaser

- Sand with 220-grit paper

- V-groove the crack for better penetration

- Remove all dust and debris

- Apply Fiberglass Resin

- Mix resin and hardener per instructions

- Apply with brush, working into crack

- Allow to penetrate completely

- Build up slightly above surface level

- Sand and Finish

- Sand with 320-grit when fully cured

- Apply gel coat if color matching needed

- Wet sand with 600-grit for smoothness

- Polish to match surrounding finish

Chip Repair Process:

- Clean chip area thoroughly

- Apply fiberglass cloth for structural repairs

- Build up in thin layers

- Sand between coats for smoothness

- Apply final gel coat layer

- Color match with appropriate tinting

Chapter 4: Advanced Techniques & Common Associated Repairs

Window Sill Repair and Replacement

Window sills often suffer damage alongside frame issues and require coordinated repair efforts.

Common Sill Problems

- Rot in wooden sills from water infiltration

- Cracking in concrete sills from freeze-thaw cycles

- Settling and separation from frame structures

- Paint failure exposing substrate to moisture

Wooden Sill Restoration

Assessment and Planning:

- Determine extent of rot damage

- Check for insect infestation

- Evaluate drainage effectiveness

- Plan for improved water management

Repair Process:

- Remove Damaged Sections

- Cut out rotted areas with precise cuts

- Preserve sound wood where possible

- Create clean, square cuts for patches

- Install Replacement Wood

- Use decay-resistant species (cedar, teak, composite)

- Cut with proper slope for drainage (1/4″ per foot minimum)

- Secure with construction adhesive and fasteners

- Seal all joints with high-quality caulk

- Improve Drainage

- Install drip edge if not present

- Add weep holes for water escape

- Ensure proper slope away from window

- Apply multiple coats of water-repellent finish

Improving Frame Seals: Weatherstripping & Caulking

Proper sealing is crucial for energy efficiency and preventing future damage.

Weatherstripping Replacement

Types of Weatherstripping:

| Type | Best Use | Lifespan | Cost |

|---|---|---|---|

| Foam Tape | Light-duty, irregular gaps | 1-2 years | Low |

| V-Strip | Double-hung windows | 5-7 years | Medium |

| Door Shoe | Bottom seals | 3-5 years | Medium |

| Compression Seal | High-traffic areas | 7-10 years | High |

Installation Steps:

- Remove old weatherstripping completely

- Clean surface with degreaser

- Measure and cut new material accurately

- Install with proper compression (not too tight)

- Test window operation after installation

Professional Caulking Techniques

Choosing the Right Caulk:

- Silicone: Excellent adhesion, paintable versions available

- Polyurethane: Extremely durable, handles movement well

- Acrylic Latex: Easy cleanup, paintable, good for interior

- Butyl Rubber: Superior water resistance, flexible

Application Best Practices:

- Surface Preparation

- Remove all old caulk completely

- Clean with appropriate solvent

- Mask adjacent surfaces for clean lines

- Prime porous surfaces if recommended

- Application Technique

- Cut tube tip at 45-degree angle

- Maintain consistent pressure and speed

- Push caulk into joint rather than pulling

- Tool immediately with wet finger or tool

- Finishing

- Remove masking tape while caulk is wet

- Allow full cure time before painting

- Check for shrinkage and reapply if needed

Addressing Condensation Issues

Condensation problems often indicate seal failures or ventilation issues.

Identifying Condensation Sources

- Interior condensation: Usually humidity control issue

- Between panes: Seal failure requiring glass unit replacement

- Exterior condensation: Normal on efficient windows

- Frame condensation: Thermal bridging or air leaks

Solutions by Type

Interior Condensation:

- Improve ventilation with exhaust fans

- Use dehumidifiers in problem areas

- Ensure adequate air circulation

- Consider storm windows for single-pane units

Seal Failure Condensation:

- Professional glass unit replacement usually required

- Temporary fixes rarely effective long-term

- Consider full window replacement if multiple units affected

- Document for warranty claims if applicable

Chapter 5: Cost Analysis: DIY Repair vs. Professional Hire vs. Full Replacement

Average DIY Repair Costs by Material Type

Understanding the financial implications helps you make informed decisions about how to repair home windows frame projects.

Wood Frame Repair Costs

| Repair Type | Materials Cost | Time Investment | Skill Level |

|---|---|---|---|

| Minor rot treatment | $25-50 | 4-6 hours | Intermediate |

| Section replacement | $50-100 | 8-12 hours | Advanced |

| Full frame restoration | $100-200 | 16-24 hours | Expert |

| Paint and refinish | $30-60 | 6-8 hours | Beginner |

Factors Affecting Cost:

- Wood species: Pine ($2-4/linear foot) vs. hardwood ($8-15/linear foot)

- Complexity: Simple rectangular vs. decorative profiles

- Access: Ground level vs. second story installation

- Additional damage: Sill, trim, or structural issues

Vinyl Frame Repair Costs

| Repair Type | Materials Cost | Time Investment | Success Rate |

|---|---|---|---|

| Small crack repair | $15-30 | 2-3 hours | 85% |

| Hole patching | $20-40 | 3-4 hours | 70% |

| Color restoration | $25-50 | 4-6 hours | 90% |

| Warping correction | $40-80 | 6-8 hours | 50% |

Vinyl Repair Limitations:

- Color matching can be challenging

- Structural repairs often temporary

- Temperature sensitivity affects repair success

- Some damage types not cost-effective to repair

Aluminum Frame Repair Costs

| Repair Type | Materials Cost | Professional Look | Durability |

|---|---|---|---|

| Dent removal | $20-40 | Good | Excellent |

| Corrosion treatment | $30-60 | Very Good | Good |

| Scratch repair | $15-35 | Fair to Good | Good |

| Complete refinishing | $80-150 | Excellent | Excellent |

Professional Repair Cost Ranges

Professional repairs typically cost 3-5 times material costs when including labor.

Typical Professional Pricing

Hourly Rates:

- Handyman services: $40-60/hour

- Window specialists: $60-80/hour

- Restoration experts: $80-120/hour

Common Repair Estimates:

| Service | Low End | High End | Average |

|---|---|---|---|

| Wood rot repair | $150 | $400 | $275 |

| Frame section replacement | $200 | $600 | $400 |

| Vinyl crack repair | $100 | $250 | $175 |

| Aluminum refinishing | $180 | $450 | $315 |

| Weatherization package | $120 | $300 | $210 |

Window Replacement Costs for Context

Full replacement costs help put repair expenses in perspective.

Replacement Cost Factors

Window Type:

- Single-hung vinyl: $250-450 installed

- Double-hung wood: $400-800 installed

- Casement windows: $350-650 installed

- Custom or historic: $800-1500+ installed

Additional Costs:

- Permit fees: $50-200

- Trim and finishing: $100-300 per window

- Disposal fees: $25-50 per window

- Unexpected repairs: $100-500 contingency

Decision-Making Calculator

Repair if:

- Total repair cost < 30% of replacement cost

- Frame structure is sound

- Windows are less than 15 years old

- Aesthetic issues only, no functional problems

Replace if:

- Repair cost > 50% of replacement cost

- Multiple problems present

- Windows are more than 20 years old

- Energy efficiency is poor

Consider Professional Repair if:

- DIY repair cost > 60% of professional repair

- Lack of tools or experience

- Historical significance requires expertise

- Warranty coverage desired

Interactive Decision Tree

Question 1: What’s the extent of damage?

- Minor (cosmetic): → DIY repair recommended

- Moderate (functional impact): → Compare costs

- Severe (structural): → Professional evaluation needed

Question 2: What’s your skill level?

- Beginner: → Simple repairs only

- Intermediate: → Most repairs feasible

- Advanced: → Complex repairs possible

Question 3: What’s your time availability?

- Limited: → Consider professional service

- Moderate: → Straightforward DIY projects

- Abundant: → Complex DIY feasible

Chapter 6: When to Call a Professional Window Repair Service

Situations Requiring Professional Intervention

While many window frame repairs are DIY-friendly, certain situations demand professional expertise for safety, effectiveness, and long-term success.

Structural Damage Assessment

Extensive Rot Issues: When rotted window frame repair involves more than 40% of the frame structure, professional assessment is crucial. Structural engineers or experienced contractors can determine if the frame can be salvaged or if complete replacement is necessary.

Load-Bearing Considerations:

- Windows in load-bearing walls

- Large window openings (over 6 feet wide)

- Multiple adjacent windows with damage

- Signs of wall settlement or movement

Complex Repair Scenarios

Multiple Window Coordination: When several windows need repair simultaneously, professionals can:

- Ensure consistent repair methods

- Coordinate material ordering for color matching

- Complete work efficiently with proper equipment

- Identify underlying causes affecting multiple units

Historic Window Preservation: Historic windows require specialized knowledge:

- Period-appropriate materials and techniques

- Compliance with preservation standards

- Specialized tools and restoration methods

- Documentation for historic tax credits

Safety-Critical Situations

Second Story and Higher:

- Specialized ladder and scaffolding equipment

- Fall protection requirements

- Insurance and liability considerations

- Efficient completion minimizing exposure time

Hazardous Materials:

- Lead paint in pre-1978 homes

- Asbestos in older caulks and sealants

- Specialized disposal requirements

- EPA RRP (Renovation, Repair, Painting) certification needed

Tips for Choosing a Qualified Professional

Licensing and Insurance Verification

Essential Credentials:

- General contractor license (where required)

- Liability insurance minimum $1 million

- Workers’ compensation coverage

- Bonding for larger projects

Verification Steps:

- Check license status with state board

- Verify insurance with carrier directly

- Confirm Better Business Bureau rating

- Review online reviews and complaints

Specialization and Experience

Look for Specialists in:

- Window restoration and repair

- Your specific window type (wood, vinyl, aluminum)

- Historic preservation (if applicable)

- Energy efficiency improvements

Experience Indicators:

- Minimum 5 years in window repair

- Portfolio of similar projects

- References from recent customers

- Manufacturer certifications for specific products

Quality Indicators

Professional Consultation:

- Thorough inspection and diagnosis

- Written estimates with detailed scope

- Multiple repair options presented

- Timeline and process explanation

- Material specifications provided

Red Flags to Avoid:

- Door-to-door solicitation

- Pressure for immediate decision

- Cash-only payment requests

- No written contract or warranty

- Significantly low bids (50% below others)

Questions to Ask Potential Contractors

Project-Specific Questions

Scope and Approach:

- “What specific repair method do you recommend and why?”

- “How will you match existing materials and finishes?”

- “What’s your warranty policy on repairs?”

- “How do you handle unexpected issues discovered during work?”

Timeline and Process:

- “What’s the estimated timeline for completion?”

- “How will weather delays be handled?”

- “What cleanup and debris removal is included?”

- “Will you obtain necessary permits?”

Business and Quality Questions

Experience and Qualifications:

- “How many similar projects have you completed this year?”

- “Can you provide references from recent customers?”

- “What manufacturer certifications do you hold?”

- “How do you stay current with new products and techniques?”

Financial and Legal:

- “What’s your payment schedule?”

- “Is financing available for larger projects?”

- “How do you handle change orders and additional costs?”

- “What happens if I’m not satisfied with the work?”

Getting and Comparing Estimates

Information to Provide:

- Detailed description of damage or issues

- Photos of problem areas

- Your timeline preferences

- Budget range expectations

- Any specific material preferences

Estimate Comparison Factors:

- Material specifications and quality levels

- Labor scope and inclusion details

- Timeline and completion schedules

- Warranty terms and coverage

- Total cost including permits and cleanup

Professional Service Benefits

Quality and Longevity Advantages

Superior Results:

- Professional-grade tools and equipment

- Access to contractor-only materials

- Proven techniques and best practices

- Quality control and inspection processes

Long-Term Value:

- Extended warranties on work performed

- Proper permits and code compliance

- Insurance coverage for work-related issues

- Established relationships for future service

Time and Convenience Benefits

Efficiency:

- Faster completion with experienced crews

- Coordination of multiple trades if needed

- Material procurement and delivery

- Cleanup and disposal included

Peace of Mind:

- Licensed and insured professionals

- Warranty protection on repairs

- No personal tool investment required

- Expert problem-solving capabilities

Chapter 7: Preventative Maintenance: Keep Your Window Frames Healthy

Regular Inspection Schedule & Checklist

Preventative maintenance is the key to avoiding major repair rotten wood window frame projects and extending the life of all window frame materials.

Seasonal Inspection Timeline

Spring Inspection (March-April):

- Assess winter damage from ice and snow

- Check for water infiltration evidence

- Test window operation after winter

- Plan summer maintenance projects

Summer Maintenance (June-August):

- Perform major cleaning and repairs

- Apply protective coatings and finishes

- Replace weatherstripping if needed

- Address any operational issues

Fall Preparation (September-October):

- Final cleaning before winter

- Check and refresh caulking

- Ensure proper drainage

- Storm window installation if applicable

Winter Monitoring (December-February):

- Watch for condensation issues

- Monitor for ice dam formation

- Check for drafts and air leaks

- Document problems for spring repair

Comprehensive Inspection Checklist

Exterior Frame Assessment:

□ Paint and Finish Condition

- Look for peeling, cracking, or fading

- Check for bare wood exposure

- Note chalking on painted surfaces

- Assess stain penetration on wood

□ Structural Integrity

- Test frame stability with gentle pressure

- Look for separation at joints

- Check for warping or bowing

- Assess corner square and alignment

□ Weatherproofing Elements

- Inspect caulk lines for cracks or gaps

- Check weatherstripping condition

- Assess storm window fit and seal

- Look for water staining or damage

□ Hardware and Operation

- Test window opening and closing

- Check lock and handle function

- Assess screen fit and condition

- Lubricate moving parts as needed

Interior Frame Assessment:

□ Moisture and Air Infiltration

- Check for condensation patterns

- Look for water stains or discoloration

- Feel for air leaks around frame

- Assess insulation condition

□ Finish and Cosmetic Issues

- Note paint or stain condition

- Check for wood movement or cracking

- Assess caulk condition at interior trim

- Look for insect activity or damage

Cleaning Tips for Different Frame Materials

Wood Frame Cleaning and Care

Regular Cleaning (Monthly):

- Dust Removal

- Use soft brush or vacuum with brush attachment

- Pay attention to corners and detailed areas

- Remove cobwebs and debris accumulation

- Surface Cleaning

- Mix mild dish soap with warm water

- Use soft cloth, avoiding abrasive materials

- Rinse with clean water and dry immediately

- Never allow water to stand on wood surfaces

Deep Cleaning (Annually):

- Paint Preparation Cleaning

- Use TSP (trisodium phosphate) solution

- Scrub with soft bristle brush

- Rinse thoroughly and allow complete drying

- Sand lightly if planning to repaint

- Natural Wood Restoration

- Use specialized wood cleaners for stained surfaces

- Apply wood brightener if weathered

- Allow proper drying time between products

- Apply wood conditioner before staining

Vinyl Frame Cleaning Protocol

Routine Maintenance (Bi-monthly):

- Basic Cleaning

- Mix 1/3 cup liquid laundry detergent

- Add to 6 gallons of warm water

- Use soft cloth or sponge for application

- Rinse thoroughly with garden hose

- Stubborn Stain Removal

- Create paste with baking soda and water

- Apply to stained areas and let sit 10 minutes

- Scrub gently with soft brush

- Rinse completely and dry with clean cloth

Restoration Cleaning (Annually):

- Oxidation Removal

- Use commercial vinyl cleaner/restorer

- Apply with microfiber cloth in circular motions

- Allow product to penetrate per instructions

- Buff to restore original luster

- UV Protection Application

- Apply vinyl protectant after cleaning

- Use products with UV inhibitors

- Avoid petroleum-based products

- Reapply every 6 months in sunny climates

Aluminum Frame Maintenance

Corrosion Prevention (Quarterly):

- Basic Cleaning

- Use mild automotive car wash soap

- Apply with soft cloth or sponge

- Pay special attention to joints and corners

- Rinse thoroughly and dry immediately

- Oxidation Treatment

- Use aluminum polish for light oxidation

- Apply fine automotive rubbing compound for heavier oxidation

- Work in small sections to prevent drying

- Buff with clean cloth to restore shine

Annual Deep Maintenance:

- Protective Coating Application

- Apply automotive paste wax or specialized aluminum protectant

- Use microfiber application cloth

- Allow to haze, then buff to shine

- Focus on exposed areas and corners

Importance of Proper Exterior Drainage and Grading

Water Management Fundamentals

Drainage Slope Requirements:

- Minimum 6 inches drop in first 10 feet from foundation

- Window sill slope of 1/4 inch per foot minimum

- Gutter and downspout proper sizing and maintenance

- French drains for persistent water issues

Common Drainage Problems

Grading Issues:

- Soil settled against foundation

- Flower beds creating water retention

- Concrete slabs directing water toward house

- Inadequate surface drainage systems

Solutions and Improvements:

- Soil Grading Correction

- Add clean fill dirt to create proper slope

- Use clay soil for water-shedding properties

- Avoid organic materials that retain moisture

- Maintain slope through regular inspection

- Hardscape Improvements

- Install splash blocks at downspouts

- Create permeable walkways and patios

- Add drainage channels where needed

- Ensure proper caulking at concrete interfaces

Repainting and Resealing Schedules

Wood Frame Maintenance Timeline

Paint System Maintenance:

| Climate Zone | Repaint Frequency | Touch-up Frequency |

|---|---|---|

| Moderate/Dry | Every 7-10 years | Every 2-3 years |

| Humid/Wet | Every 5-7 years | Every 1-2 years |

| Coastal/Salt | Every 3-5 years | Annually |

| Extreme Weather | Every 4-6 years | Every 1-2 years |

Preparation Requirements:

- Surface cleaning with appropriate cleaner

- Scraping and sanding loose or peeling areas

- Primer application on bare wood surfaces

- Caulk replacement at all joints and seams

Quality Paint Selection:

- 100% acrylic latex for exterior durability

- High-quality primer for maximum adhesion

- Mildew-resistant formulations in humid climates

- UV-resistant pigments for color retention

Sealant Replacement Schedule

Caulk Inspection and Replacement:

Annual Inspection Points:

- Window frame to siding interfaces

- Interior trim to wall connections

- Sill to frame connections

- Glass to frame seals (if applicable)

Replacement Indicators:

- Cracks or gaps in caulk line

- Shrinkage pulling away from surfaces

- Discoloration or mildew growth

- Loss of flexibility (brittle or hard)

Seasonal Replacement Timing:

- Best time: Late spring/early summer

- Temperature requirements: 40-80°F for application

- Humidity considerations: Low humidity for faster curing

- Weather forecast: No rain for 24-48 hours after application

Stain and Natural Finish Maintenance

Penetrating Stain Schedule:

- Semi-transparent stains: Every 2-4 years

- Solid color stains: Every 4-6 years

- Clear sealers: Every 1-2 years

- Oil-based finishes: Every 2-3 years

Application Best Practices:

- Surface Preparation

- Clean with deck/fence cleaner

- Allow 48 hours drying time

- Sand lightly if previous finish is peeling

- Apply wood conditioner if recommended

- Application Technique

- Use high-quality brush or pad applicator

- Work in manageable sections

- Maintain wet edge to avoid lap marks

- Back-brush for even penetration

Chapter 8: Frequently Asked Questions

General Window Frame Repair Questions

Q: How do I know if my window frame damage requires professional repair or if I can handle it myself?

A: The decision depends on several factors: damage extent, your skill level, and safety considerations. DIY repairs work well for cosmetic issues like small cracks, minor rot (less than 25% of frame), paint problems, and simple weatherstripping replacement. However, call professionals for structural damage, extensive rot, second-story work, historic windows, or when multiple windows need coordinated repair. If you’re unsure, most professionals offer free estimates that can help you understand the scope of work needed.

Q: What’s the most common mistake people make when attempting DIY window frame repairs?

A: The biggest mistake is not addressing the underlying cause of the damage. For example, treating rotted window frame repair without fixing the water infiltration source will result in recurring problems. Other common errors include:

- Skipping surface preparation steps

- Using incompatible materials (like oil-based paint over latex)

- Not allowing proper drying/curing time between steps

- Attempting repairs in poor weather conditions

- Underestimating the time and skill required

Q: How long do DIY window frame repairs typically last compared to professional work?

A: Well-executed DIY repairs using quality materials can last just as long as professional work—often 5-15 years depending on the repair type and environmental conditions. The key factors for longevity are:

- Proper surface preparation

- Using appropriate materials for your climate

- Following manufacturer instructions completely

- Addressing underlying causes of damage

- Regular maintenance after repair

Professional repairs may last longer due to superior materials access, specialized tools, and extensive experience, but the difference is often marginal when DIY work is done correctly.

Material-Specific Questions

Q: Can I paint vinyl or aluminum window frames after repair?

A: Vinyl frames: Modern vinyl can be painted with specialized vinyl-safe paints that won’t cause heat-related warping. Use paints specifically designed for vinyl, typically lighter colors that reflect heat. The paint manufacturer should specify vinyl compatibility on the label.

Aluminum frames: Yes, aluminum frames paint very well after proper preparation. The key is using an etching primer designed for aluminum, which ensures proper paint adhesion. Clean thoroughly, sand lightly, apply aluminum primer, then finish with high-quality exterior paint.

Important: Both materials require thorough cleaning and appropriate primer for successful, long-lasting paint jobs.

Q: How long does epoxy wood repair last, and is it as strong as new wood?

A: High-quality two-part epoxy wood repairs can last 15-25 years or more when properly applied. Modern structural epoxies are often stronger than the surrounding wood and won’t shrink, crack, or rot like traditional wood fillers.

Longevity factors:

- Quality of epoxy: Marine-grade epoxies last longest

- Surface preparation: Complete rot removal essential

- Application conditions: Proper temperature and humidity

- Protective finish: Quality paint or stain system over repair

Strength comparison: Epoxy repairs typically exceed the strength of the original wood, making them excellent for structural applications. However, they’re harder than wood, so expansion/contraction rates differ slightly.

Q: What’s the best caulk for window frames in different climates?

A: Caulk selection should match your specific climate conditions:

Humid/Wet Climates:

- Silicone caulk: Superior water resistance, flexible

- Polyurethane caulk: Excellent durability, handles movement

- Look for: Mildew resistance, 50+ year warranty

Dry/Desert Climates:

- Acrylic latex with silicone: Good adhesion, paintable

- 100% silicone: UV resistance, temperature stability

- Look for: UV stabilizers, temperature range rating

Cold/Freeze Climates:

- Polyurethane: Best cold-weather flexibility

- Hybrid polymer: Good all-weather performance

- Look for: Low-temperature flexibility, freeze-thaw resistance

Coastal/Salt Air:

- Marine-grade silicone: Corrosion resistance

- Polyurethane: Chemical resistance properties

- Look for: Salt spray resistance ratings

Cost and Value Questions

Q: Are DIY window frame repairs as good as professional ones in terms of home value?

A: Well-executed DIY repairs can provide equal value benefits, but several factors affect this:

Positive Value Impact:

- Professional appearance and quality

- Proper materials and techniques used

- Documentation of work performed

- Warranty or guarantee provided

Potential Value Limitations:

- Visible amateur workmanship

- Use of incorrect or cheap materials

- Incomplete repair addressing symptoms not causes

- No professional warranty backing

Best practices for value:

- Take before/after photos

- Keep receipts for quality materials

- Follow manufacturer specifications exactly

- Consider professional consultation for complex issues

- Maintain detailed records of work performed

Q: Should I repair or replace old windows for best return on investment?

A: The decision depends on several economic factors:

Repair When:

- Windows are less than 20 years old

- Frames are structurally sound

- Repair costs less than 40% of replacement

- Windows have historic or architectural value

- Energy performance is acceptable

Replace When:

- Multiple major problems exist

- Windows are more than 25 years old

- Energy efficiency is very poor

- Repair costs exceed 60% of replacement

- Significant operational problems persist

Financial considerations:

- Energy savings from new efficient windows

- Tax credits available for energy-efficient replacements

- Maintenance costs over next 10-15 years

- Resale value impact in your market

Technical and Safety Questions

Q: How do I test for lead paint before starting window frame repairs?

A: Lead testing is crucial for homes built before 1978:

Testing Methods:

- DIY test kits: Available at hardware stores, give preliminary results

- Professional testing: More accurate, required for renovation work

- Laboratory analysis: Most accurate for chip samples

Legal Requirements:

- EPA RRP Rule: Contractors must be certified for lead-safe work practices

- DIY homeowners: Not legally required to follow RRP rules but highly recommended for safety

- Disclosure: Required when selling homes built before 1978

Safety Measures if Lead Present:

- Wet scraping methods only (no dry sanding)

- HEPA vacuum for cleanup

- Plastic sheeting to contain debris

- Proper respirator protection

- Specialized disposal of contaminated materials

Q: What safety equipment do I absolutely need for window frame repair?

A: Essential safety equipment varies by repair type:

Basic Safety (All Repairs):

- Safety glasses or goggles

- Work gloves (cut-resistant for glass work)

- Dust mask (N95 minimum)

- Knee pads for comfort and safety

Chemical Work (Strippers, Solvents):

- Chemical-resistant gloves

- Respirator with appropriate cartridges

- Eye protection with side shields

- Long sleeves and pants

Height Work (Second Story+):

- Proper ladder (1:4 ratio setup)

- Ladder stabilizers or standoffs

- Tool belt to keep hands free

- Spotter person recommended

Power Tool Work:

- Hearing protection

- Face shield for grinding/cutting

- Dust collection when possible

- Proper clothing (no loose items)

Q: How can I tell if window frame damage is affecting my home’s energy efficiency?

A: Detection methods for energy loss:

Visual Inspection:

- Daylight visible around closed windows

- Curtains or blinds moving from air currents

- Condensation patterns indicating air leaks

- Ice formation or frost patterns in winter

Physical Testing:

- Hand test: Feel for air movement around frames

- Smoke test: Use incense stick to detect air currents

- Thermal imaging: Shows temperature differences (professional or rental equipment)

- Blower door test: Professional whole-house air leakage assessment

Utility Bill Analysis:

- Seasonal heating/cooling cost increases

- Comparison with similar homes

- Utility company energy audits

- Smart thermostat data analysis

Quantifying Impact:

- Air leaks can increase energy costs 10-20%

- Professional energy audit provides specific measurements

- Payback calculations for repair vs. replacement decisions

Maintenance and Prevention Questions

Q: How often should I inspect my window frames, and what should I look for?

A: Inspection frequency:

- Detailed inspection: Twice yearly (spring and fall)

- Quick visual check: Monthly during extreme weather

- Professional inspection: Every 5-10 years or after severe weather

Spring Inspection Checklist:

- Water damage from winter moisture

- Paint or finish deterioration

- Caulk condition and adhesion

- Window operation and hardware function

- Insect activity or damage signs

Fall Inspection Checklist:

- Summer weather damage assessment

- Weatherstripping condition

- Preparation for winter conditions

- Drainage system function

- Storm window installation needs

Monthly Monitoring:

- Condensation patterns changes

- New cracks or damage

- Operational problems

- Unusual drafts or air leaks

Q: What’s the single most important thing I can do to prevent window frame problems?

A: Water management is the most critical factor. Most window frame problems trace back to moisture infiltration. Key prevention strategies:

Exterior Water Control:

- Maintain proper grading away from house

- Keep gutters and downspouts clean and functional

- Ensure siding and trim are properly caulked

- Install or maintain adequate roof overhangs

Frame-Specific Protection:

- Apply quality exterior caulk at all joints

- Maintain paint or stain systems for weather protection

- Replace weatherstripping when worn

- Ensure proper window sill slope and drainage

Interior Moisture Control:

- Use exhaust fans in bathrooms and kitchens

- Maintain appropriate humidity levels (30-50%)

- Address air leaks that cause condensation

- Monitor for signs of moisture problems

Q: Can I repair window frames in winter, or should I wait for warmer weather?

A: Temperature and weather constraints for repairs:

Acceptable Winter Repairs:

- Interior caulking and weatherstripping

- Minor wood filling with appropriate products

- Hardware adjustment and lubrication

- Paint touch-ups in heated, ventilated areas

Wait for Spring:

- Exterior painting (most paints require 50°F+)

- Major caulking projects (curing issues in cold)

- Epoxy repairs (temperature-sensitive curing)

- Any work requiring extended outdoor exposure

Cold Weather Considerations:

- Material storage: Keep products at room temperature

- Application conditions: Follow manufacturer temperature guidelines

- Curing time: Allow extra time for chemical reactions

- Safety factors: Ice, snow, and shortened daylight increase risks

Emergency Repairs:

- Temporary weatherproofing with plastic sheeting

- Interior draft sealing until permanent repairs possible

- Prevent further damage until proper repair conditions exist

Conclusion

Mastering how to repair home windows frame effectively is one of the most valuable home maintenance skills you can develop. Whether you’re dealing with rotted window frame repair on cherished wooden windows or need to repair rotten wood window frame sections to restore your home’s energy efficiency, the techniques and strategies covered in this guide provide you with professional-level knowledge and confidence.

Key Takeaways for Successful Window Frame Repair

Foundation Principles:

- Always address the underlying cause of damage, not just symptoms

- Proper surface preparation is crucial for lasting repairs

- Use high-quality materials appropriate for your climate

- Allow adequate time for each step in the repair process

Material-Specific Success Factors:

- Wood repairs require moisture control and proper wood preservation

- Vinyl repairs need compatible materials and temperature awareness

- Aluminum repairs focus on corrosion prevention and proper priming

- Fiberglass repairs use automotive-style techniques for best results

Long-term Value Creation:

- Preventative maintenance saves money and extends window life

- Regular inspections catch problems before they become expensive

- Quality repairs can provide 10-20 years of reliable service

- Professional consultation adds value for complex issues

Your Next Steps

Immediate Actions:

- Conduct a thorough inspection of all your window frames using the checklists provided

- Prioritize repairs based on severity and potential for further damage

- Gather appropriate tools and materials for your specific repair needs

- Plan your repair schedule around weather conditions and material requirements

Building Your Skills:

- Start with simpler repairs to build confidence and experience

- Document your work with photos for future reference

- Keep detailed records of materials and techniques used

- Consider taking on more complex projects as skills develop

Professional Partnership:

- Develop relationships with quality contractors for major projects

- Use professional consultations to validate your repair plans

- Consider professional work for safety-critical or historic windows

- Maintain professional contacts for future complex repairs

Final Encouragement

Window frame repair might seem daunting initially, but with the right knowledge, tools, and approach, most homeowners can successfully tackle these projects. The satisfaction of restoring your windows to proper function, improving your home’s energy efficiency, and saving significant money makes the effort worthwhile.

Remember that every expert started as a beginner, and each repair project builds your skills and confidence. Whether you choose to handle simple maintenance tasks yourself while leaving complex structural work to professionals, or you develop into an advanced DIY repair specialist, the knowledge in this guide provides the foundation for success.

Take action today by inspecting your window frames, identifying priority repairs, and taking the first steps toward healthier, more efficient windows that will serve your home well for years to come.

Author Bio & Expertise

This comprehensive guide was developed by drawing from decades of combined experience in window repair, restoration, and home improvement. The techniques and recommendations presented reflect current industry best practices, manufacturer specifications, and field-tested methods that deliver reliable, long-lasting results.

Areas of Expertise:

- Residential window repair and restoration

- Historic window preservation techniques

- Energy efficiency improvement strategies

- Material science and compatibility

- Safety protocols and best practices

Continuing Education:

- Regular participation in industry training programs

- Manufacturer certification maintenance

- Building code and regulatory compliance updates

- New technology and material evaluation

For additional resources, detailed product specifications, or specific technical questions not covered in this guide, consult with local building professionals, material manufacturers, or extension service specialists in your area.

This guide serves as educational material for homeowner reference. Always consult local building codes, manufacturer specifications, and safety guidelines before beginning any repair project. Consider professional consultation for complex repairs, safety-critical work, or when in doubt about proper procedures.

Get Your Free Window Repair Estimate Today!

Don’t let window damage compromise your home’s comfort and efficiency.

Contact Windows Repair in Gibraltar

(+350) 056021155

✉️ contact@windowsrepairgib.com